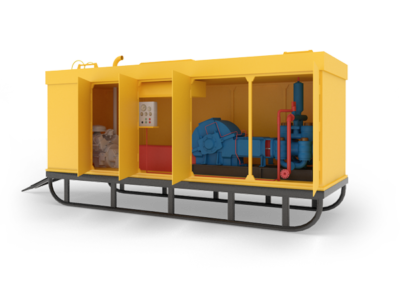

Sledge-mounted pressurising unit

From 2 800 000 ₽

In stock

Purpose

The pressurising unit is designed for hydraulic tests of main pipelines for strength and tightness.

Technical specifications

| Unit type | Containerised on a sledge |

| Motor(type) | diesel |

| Model | YaMZ-238 M2 or YaMZ-236 NE2 |

| Nominal power, kW | 176 |

| High-pressure pump | NC-320 |

| Limit setting of pressure relief valve, MPa (kgf/cm2) | 18,5 (185) |

| Ideal flow rate at 1935 engine rpm, l/sec (l/min) — at the lowest pressure — at the highest pressure |

3,7 (221,7) |

| Overall dimensions, mm | 5665 х 1540 х 2450 |

The quality of the pipes is the most important factor when laying any pipeline. Therefore, it is necessary to check each pipe section directly during installation. It is extremely difficult to do this manually (visually) and the installation of defective pipes is inevitable. What can result from installing a poor quality or damaged pipe? From inevitable repair of an already installed pipe section, to repair of damaged neighbouring sections, e.g. in case of an explosion or a large leakage of raw materials. To avoid undesirable costs and time, it is essential to check all pipes in advance.

Pressurising unit – is a special machine that pumps water into the pipeline to create increased pressure. This pressure makes it possible to immediately identify any deficiencies in the strength and tightness of the pipeline. Such a pressure test is carried out very quickly and helps to avoid high costs during subsequent repairs. When laying any pipeline, the most important factor is the quality of the pipes. That is why it is necessary to check each pipe section directly during installation. It is extremely difficult to do this manually (visually), and installation of defective pipes is inevitable. What can result from installing a poor quality or damaged pipe? From inevitable repair of an already installed pipe section, to repair of damaged neighbouring sections, e.g. in case of an explosion or a large leakage of raw materials. To avoid undesirable costs and time, it is necessary to check all pipes in advance.

The pressurising unit consists of a combustion engine, a plunger or piston pump and a frame. The pressurising unit also includes discharge pipes, shut-off valves and suction hoses. In most cases, the assembled unit is mounted on a vehicle chassis or a special trolley.

When installing long-distance pipelines, a pressurising unit with a head from 8 to 40 MPa and a capacity from 12 to 83 cubic metres per hour is used.

Modern pressurising units can be operated individually or combined. The second option is possible when several units are connected in parallel.

If a large-diameter pipeline is to be tested, which are pipelines with a diameter of more than 1220 mm, a group of pressurising units is used, which are located 75-110 kilometres apart.